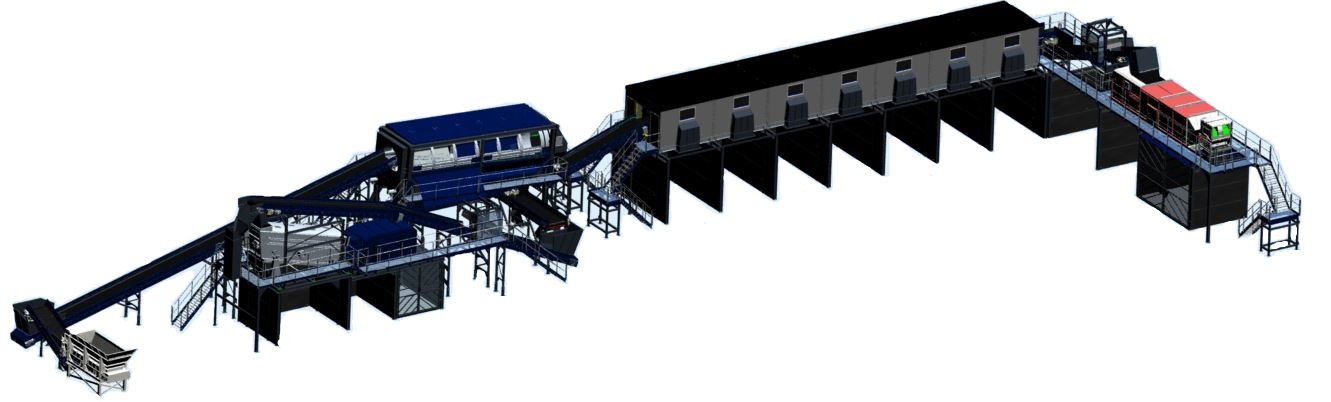

Blue London have recently supplied a BlueMAC plant to Westminster Waste for their new site in South East London. Westminster Waste was set up in December 2010 by Managing Director Dominic Moule, and has grown swiftly over the last 6 years, now employing over 70 staff. Originally the business began processing waste at a compact site in Bermondsey, and while this site is still utilised by the business today, their main operation is now at a new 3 acre site in Charlton. Processing C&D waste is the core function of the business which is brought in by a fleet of 30 Westminster Waste vehicles and also third party ‘drops’. Current volumes stand at around 1,500 tonnes per week, with the waste coming from across South East London and Kent.

The new BlueMAC recycling plant has allowed the business to recycle a much higher percentage of material. The wood waste is shredded and screened via a Doppstadt AK510K shredder and Powerscreen Warrior 1400X screen on site, to create a biomass material, while others materials are sent out for further processing and baling. The small amount of material that can’t be recycled is sent for recovery as RDF and the process is much more automated and significantly less labour intensive than previously, meaning overall costs have been reduced.