Lowmac Recycling was founded in 1973, starting life trading in secondary metals. In 1981, the company moved into waste management with the introduction of skip and roll-on-off hire for household, commercial and industrial waste collection.

The company has a secure shredding facility in Ayr and operates two purpose-built waste treatment sites in Irvine from where the company provides a large range of environmental and recycling services. These include ferrous and non-ferrous metals recycling, ELV, WEEE collection and processing, green waste processing, wood and general waste recycling, reclamation of recycled aggregates and soils and the production of animal bedding and biofuel.

The challenge was to increase the company’s waste processing capabilities and enhance the cleanliness and quality of the end-products created during the recycling process.

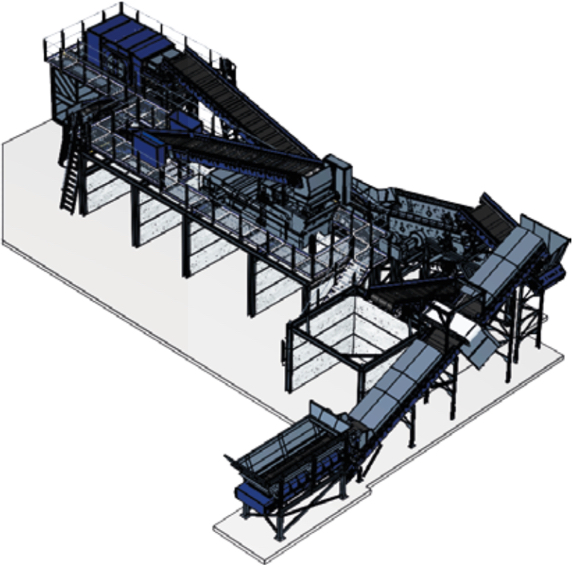

After going through a competitive tender process, Lowmac Waste & Recycling invested in an extremely versatile, tailor-made waste recycling plant. The plant currently processes a wide variety of incoming waste streams at around 1000 tonnes per week at a rate of between 25 and 30 tonnes per hour and is more than capable of greater volumes should future needs arise. The new BlueMAC waste recovery system, designed and built to combine a series of compatible processors and conveyor arrays in a convenient and compact under-cover configuration, can treat a broad range of mixedwaste and, consequently, can provide material remediation to a very high quality. Clean fines, secondary aggregates, biomass, animal bedding, ferrous and non-ferrous metals, amongst other saleable materials, are all being produced from this specially designed, multi-tasking waste recovery plant.

Depending on the material being processed, Lowmac’s new plant starts with a Powerscreen Warrior 1400 screener which ensures the incoming feed material stream is <75mm – the size for which the system has been designed.