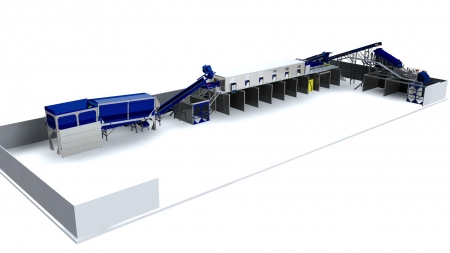

Leading manufacturing company BlueMAC has designed and built another tailor-made installation; this time for R. Collard Ltd and supplied by Blue Machinery London. The new MRF has been created to Collard’s specific requirements and is incorporated into the new 80m x 30m under-cover building at the company’s recently opened state-of-the-art recycling facility in Eversley, Hampshire – one of four recycling centres operated by Collard.

R. Collard Ltd is owned by the well known Touring Car racing driver Rob Collard and has been established for over twenty years. This versatile company is a leading demolition specialist with divisions also providing skip hire, haulage, earthworks and recycled aggregate production. Alongside these interests is a burgeoning involvement in waste management. The new MRF is part of a planned expansion of the company’s recycling activities and is a necessary investment to help cope with the steady rise in waste material volumes available for recycling, which is largely as a result of Collard’s increased demolition work and expanding skip hire activities. As well as contributing to Collard’s growth in waste management, the new MRF will play a major part in ensuring minimum tip-to-landfill from the incoming waste-stream, as well as producing high volumes of clean, saleable recycled materials. The MRF will predominantly process construction and demolition waste but, with future proof versatility built in, will be more than capable of handling other waste materials such as C&I (commercial and industrial) as the need arises.

Commenting on his company’s new acquisition, Managing Director Rob Collard said “We’ve been working with Blue Machinery London for many years and found their experience and expertise on this project to be invaluable. From the outset at the concept stage right through to installation, the communication and attention to detail were second to none. From innovative health and safety benefits to understanding our operational needs, the BlueMAC team understood our requirements throughout and I feel the success of the plant is a result of this”. Paul Donnelly, General Manager at Blue Machinery London, responded “The plant went in really well and we are delighted that our long-standing customer is pleased with the result. I’d like to thank our design and installation team for their great work and also Pete Duggan and staff at Collard for their cooperation and support throughout the project.”

The BlueMAC MRF begins with a variable speed belt feeder steadily conveying the incoming waste stream into a 2510 trommel, which removes fines at 50mm and which are then transferred on a 50 metres long transfer conveyor to the fines clean up system at the other end of the building; en route the fines pass an overband magnet which removes any ferrous metals. The material is transferred into the fines processing system by a conveyor fitted with a magnetic head roller for smaller ferrous metal extraction which is collected via a chute into a skip. The remaining material passes over a flip-flow screen for processing of fines to -10mm. The 10-50mm is then segregated through a GK air classifier for heavy and lights separation, the light fraction being ideally suited to the production of SRF (solid recovered fuel)

After the trommel the 50mm plus material passes an air separator before entering the picking station, which has been purpose-designed in a six-bay, double-sided configuration with 6 additional drop boxes for high value material such as non-ferrous metals or cabling. The station is comprised of an extra wide cabin for operatives’ safety and has been supplied complete with industrial specification on wiring, heating and lighting for a comfortable and safe working environment. The picking station’s 1500mm wide conveyor belt, with variable speed, provides optimum material spread allowing maximum recovery. An overband magnet after the picking station cleans up the remaining material, dropping ferrous metals into the same collection area as that on the fines transfer belt. The last part of the process sees the material conveyed past a secondary air separator to give a final clean to the hard core.